Minimize Fugitive Emissions

Explore Best Practices in a Two-Part On-Demand Webinar Series

Limiting Fugitive Emissions by Reducing Packing Case Leakage

Hydrocarbon gas leakage from oil and gas compression machinery has been cited as a major contributor of greenhouse gases by both the US EPA and DOE. Gas compressors have many potential leak sources where improvements can be made, either through new technology or improved maintenance and operational practices. This webinar focuses specifically on packing cases and the factors affecting packing life. We review maintenance best practices, assess possible modifications and demonstrate Cook Compression’s capabilities to minimize and control emissions.

Lowering the Carbon Footprint Through an Optimized Compressor Configuration

Reciprocating compressors that operate in a suboptimal configuration can lead to excessive and unnecessary carbon emissions. The root cause of these emissions is varied, yet most directly relate to operational efficiency and the negative ramifications of unplanned shutdowns, especially where flaring is utilized. This webinar provides detailed insight into common reciprocating compressor performance and reliability pain points and how they can be addressed. Cook Compression experts review how cylinder valves and ancillary components contribute to excessive emissions.

LEARN MORE ABOUT EMISSIONS MANAGEMENT

Controlling Compressor Emissions

Across the natural gas industry, measuring and controlling fugitive emissions has become a priority – to comply with regulations and to maximize natural gas recovery.

The experts at Cook Compression can provide a full system assessment and consult with operators on options to meet company objectives.

Identifying the Source of Emissions

Compressor emissions often originate from multiple sources, and several measures may be needed to achieve the desired level of control.

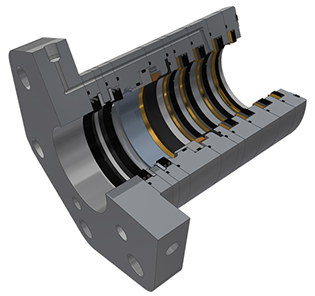

The most common source of fugitive emissions is the packing case:

- Along the piston rod

- Through the packing case nose gasket

- Between packing case cups

Other sources of fugitive emissions from the compression cylinder may include:

- Oil wiper packing

- Valve cover gaskets

- Valve unloader packing

- The distance piece vent/drain

Related Case Study

California Gas Producer Hits Emissions Target with Cook

To help a major gas producer meet local requirements to reduce cylinder emissions on 90% of its reciprocating compressors, Cook Compression implemented a comprehensive upgrade of cylinder-end components. At the heart of the upgrade was the COOK CLEAN® sealing system – a solution that also significantly improved packing case life.

Featured Products & Services

Contact Us

Every emissions problem is unique. Contact Cook Compression for the optimal solution for your application, environment and emissions goals.

Downloads

- Emissions Solutions Overview

- “Technologies, Best Practices Helping Producers Manage Compressor Emissions” (American Oil & Gas Reporter, March 2013)