Sustainability

Compressor Technologies for a Green Future

Cook Compression is joining with other industry leaders in the pursuit of a sustainable, clean energy future.

For more than a century, Cook Compression has developed innovative technologies to move the compression industry forward. In partnership with both OEMs and end users, we have long created solutions that address challenging application needs and evolving performance expectations.

We bring that same expertise and commitment to the development of green energy solutions.

Near-Zero Emissions for Net-Zero Goals

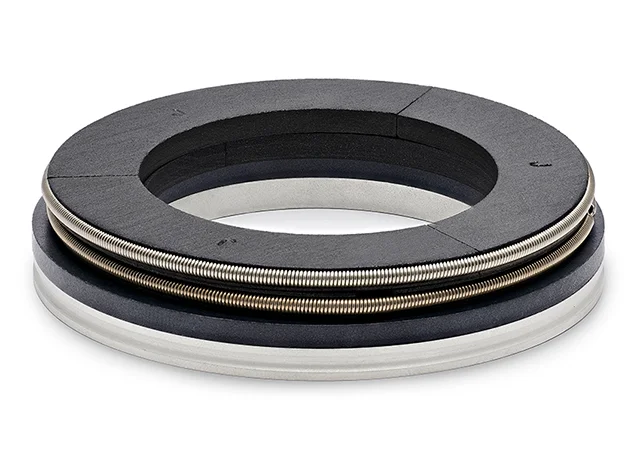

Cook Compression can provide a full suite of solutions to help you comply with regulations and maximize natural gas recovery. From COOK CLEAN® sealing systems that reduce fugitive emissions to near zero levels to a complete appraisal of your equipment to expert repair and service capabilities, we can help you meet operational and environmental objectives.

The Hydrogen Transition

A robust hydrogen economy is central to achieving a carbon-neutral energy infrastructure, transportation sector and industrial base, and Cook Compression is ready to support this transition.

Cook Compression has years of experience supporting hydrogen applications in refineries, as well as creating solutions for new challenges. Several of our proprietary TruTech® cylinder ring and rod ring materials have already proven successful in withstanding the extreme low dew point qualities of hydrogen gas. In addition, our Manley® valves and Optima™ plate valves have both proven to operate reliability in light gases, including hydrogen.

Moreover, we custom engineer each solution to its operating conditions. We work closely with our customers to understand operating parameters and design solutions to perform as needed.

Your Innovation Partner

Cook Compression and our parent company Dover Precision Components continue to make significant investments in product development capabilities to accelerate testing and provide proven technologies to the field.

With a state-of-the-art Innovation lab in Houston that allows product validation under real-life operating conditions, a dedicated materials development team working on high-performing polymers, and more than a century of field experience with compressor operation, Cook Compression is ideally positioned to advance compressor technology for the clean energy future.

TruTech® Engineered Polymer Materials

Cook Compression boasts a comprehensive line of proprietary PEEK- and PTFE-based polymer materials, backed by ongoing materials development and testing. Formulas, blending and molding are all rigorously controlled and completed in-house to ensure consistent performance characteristics.

Value Chain Solutions

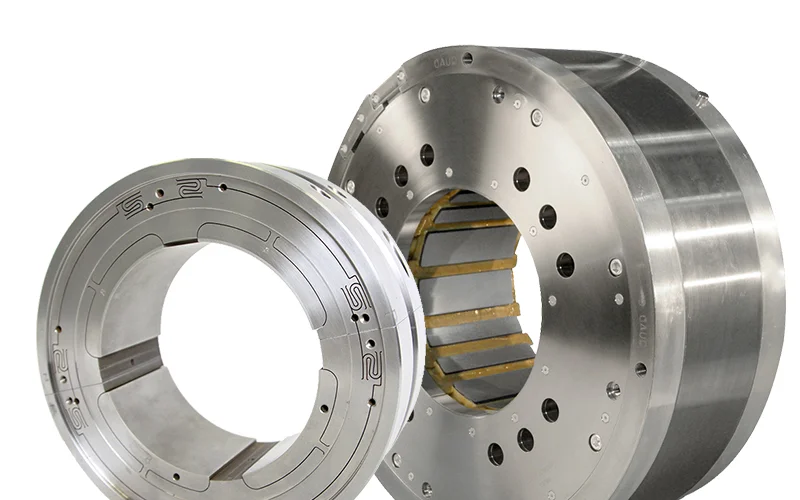

As part of Dover Precision Components, Cook Compression not only benefits from an ongoing investment in product development but also supplies broad industry knowledge and critical bearing components.

Sister brand Waukesha Bearings is an industry leader in custom-engineered fluid film bearings, as well as advanced active magnetic bearing systems. Application experience includes hermetically sealed magnetic bearings.

Talk to Our Experts

To discuss hydrogen development opportunities with our engineers, contact us today.