Lentus® Valve

Designed For High-Pressure Applications

Compressing light gases, such as hydrogen and nitrogen, creates a unique set of challenges for compressor components. Light gases are difficult to seal and their compression requires incredibly high pressures, up to 1,000 bar. Some applications, such as hydrogen mobility, call for non-lubricated compression to maintain a high gas purity. Valves for these services require high strength, good seal properties, flow efficiency, and materials that are fully compatible with this gas environment.

Building upon over 100 years of innovation, Cook Compression designed the Lentus valve to enable gas compression under these challenging circumstances.

Lentus Valve Design

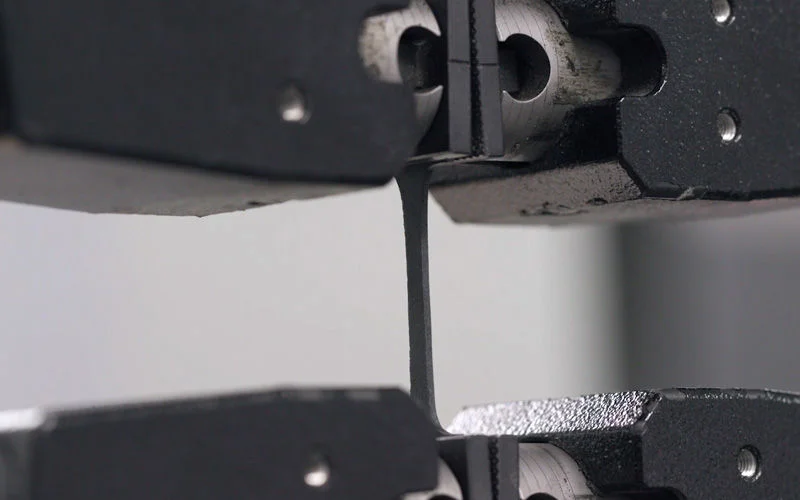

At high pressures or high-pressure ratios, a shaped seal element offers many advantages. Shaped elements can reduce tensile stress in materials, which is critical to improving material fatigue lifespan in light gas environments. It can also reduce distortions that cause leak paths due to extreme pressure loads, maximize flow efficiency, and minimize clearance volume. The Lentus valve uses metallic and polymer seal elements featuring optimized geometries to deliver an effective seal, increased flow, and reduced tensile stress levels.

Advanced Materials for Advanced Requirements

Materials transform in high-pressure, high-purity environments, and this affects material selection. The material must have high strength, good impact and wear resistance, and function in a non-lubricated environment. Surface finishing techniques and specific heat treatment processes are vital to improving valve life. Cook Compression uses advanced metallics and polymers to provide superior durability and optimum performance characteristics in light gas applications, including hydrogen mobility.

Your Partner for the Hydrogen Transition

Hydrogen plays a critical role in transforming the world’s energy infrastructure, and compression is key in enabling this transition. Diaphragm and Hydraulic compressors are most commonly used to compress hydrogen for mobility, and their valves must be carefully designed to maximize equipment life in these high-pressure applications. In addition, components must be able to withstand the high-purity environments necessary for hydrogen in vehicle fuel cells.

For over 133 years, Cook Compression has developed components critical to the performance and reliability of reciprocating compressors. Today, Cook Compression is investing in the engineering, innovation and materials development capabilities needed to support energy companies as they navigate their pathway to a carbon-neutral world. Our experience, coupled with state-of-the-art research facilities and a deep range of products and engineered polymers, enables us to quickly develop and test new technologies for the next generation of hydrogen applications.

Learn more about how Cook Compression and Dover Precision Components are creating a path to a more sustainable future.

Discover more

Lentus Valve Advantages

- Unique geometries reduce tensile stress levels

- Shaped poppet element increases flow efficiency

- Superior sealing elements reduce leakage paths

- Advanced materials withstand high-pressure and high-purity environments

- Minimized clearance volume

- Robust design through FEA (finite element analysis) method

Typical Applications

- Hydrogen fueling and mobility

- High-pressure specialty gas compression